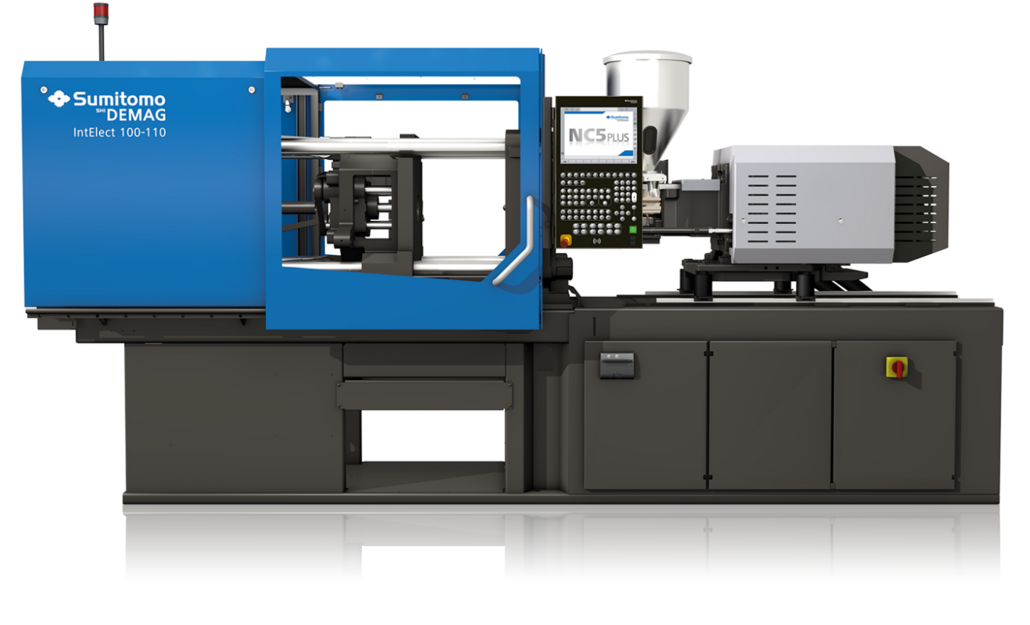

Top performance in continuous operation

Machine status at a glance

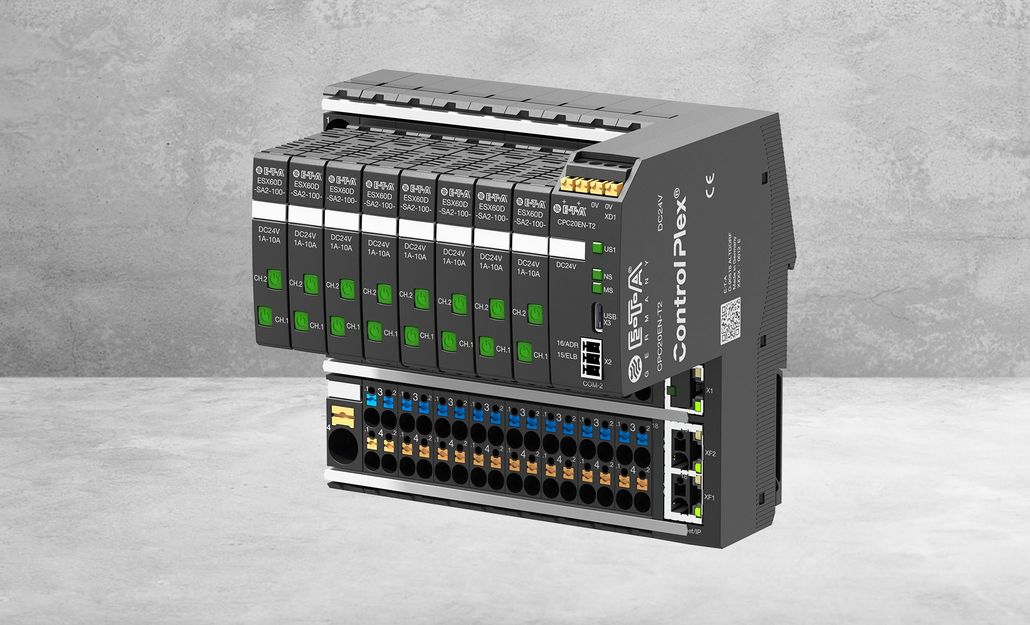

In order to keep downtimes to a minimum, the main part of injection- moulding machine maintenance is still done preventively. This strategy to increase availability is relatively expensive, as components with remaining endurance are replaced unnecessarily. To reduce maintenance costs while maintaining a high level of reliability, Sumitomo (SHI) Demag strictly relies on systems for permanent machine condition monitoring. The DC 24 V circuits are protected and monitored with our intelligent REX12 system. The system impresses with its slim design and fast and simple installation. The small space requirement helps limit the machine’s footprint. There is the option to communicate with the system control via IO link by simply changing the supply module, which enables monitoring status data, as well as actual current and voltage values.

This way of Condition Monitoring helps detect potentially critical conditions at an early stage. This reduces service costs and increases the reliability of the machine.