Highest flexibility and transparency

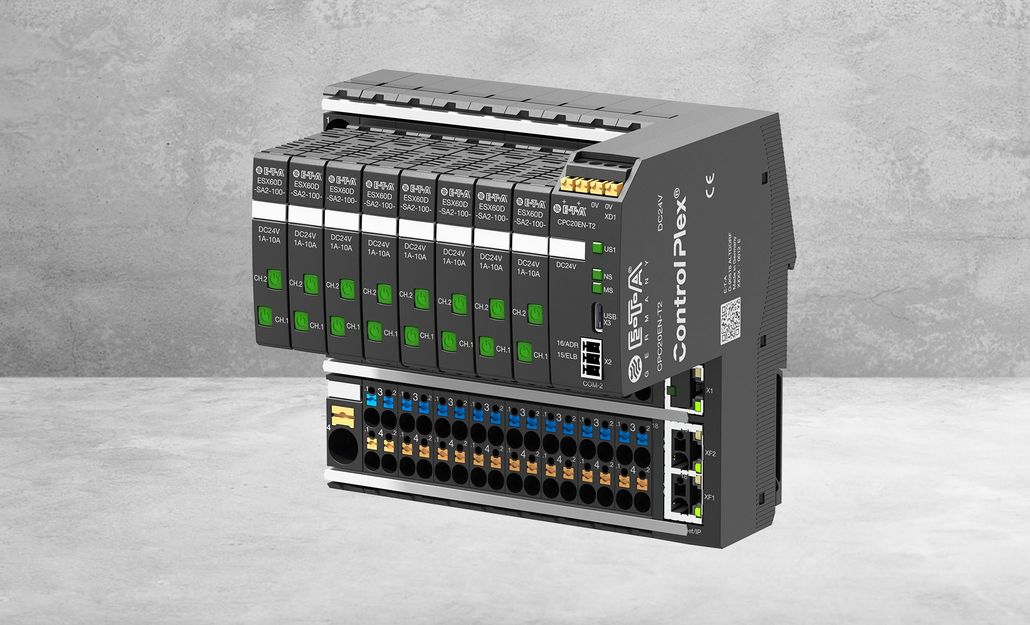

CPC20 bus controller

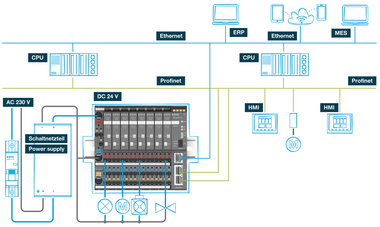

However, it can be observed that supply chains are more vulnerable, while at the same time an international standard is needed for planning manufacturing facilities. In order to facilitate service and maintenance of the systems, a uniform standard is defined as far as possible, which includes the mechanical and the entire electrical design of all components. This aspect has a decisive influence on the control systems selection. Especially for the plant construction industry, the preferred bus systems are PROFINET and Ethernet IP, which cover most of the international market in this sector. Therefore, we offer the intelligent, pluggable CPC20 protection and power distribution system with both fieldbus connections.

Pluggable systems increase system availability

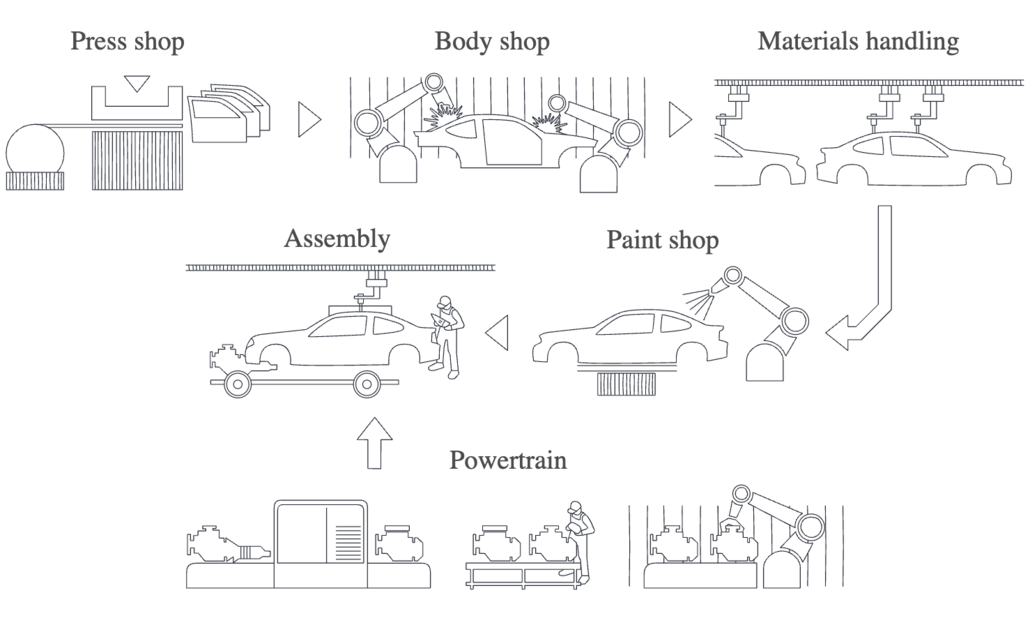

Flexibility and the ability to easily extend system components were already important factors when designing power distribution in the past. This is why the 17plus and 18plus power distribution modules have been successfully used in car manufacturing and process industry systems or more than ten years. These accommodate plug-in type circuit protectors from the thermal-magnetic or electronic portfolio.

The CPC20 increases transparency

By extending the electronic solutions with the CPC20 bus controller, they can now communicate. The ESX60D circuit protector collects measuring data, such as the current load current or the status of the circuit protectors and transfers this information to the CPC20 bus controller, where the information is collected and forwarded to the superordinate control systems. This allows a clear overview of the current situation of the DC 24 V control voltage level. Based on limit values, deviations can be detected quickly and forwarded to the superordinate control systems, helping operators react quickly to avoid machine downtimes. Moreover, this transparency enables remote access to all data. Systems can centrally be monitored and compared.

OPC UA and MQTT are implemented

Measuring data collection in systems has significantly increased in recent years. This can strain the control systems. Therefore, some companies turn to transfer the measuring data via different data channels, e.g. MQTT and OPC UA. This functionality is currently implemented in the CPC20 system. The CPC20 protection and power distribution system is designed for the international use in the plant construction and process control industry and well suitable for this thanks to its PROFINET and Ethernet IO interfaces.

Your benefits

- Increased system availability through comprehensive diagnostic functions

- Improved protection against voltage dips through selective protection of loads

- Increased flexibility of system planning through a modular terminal block system