Decentralised power for the automotive industry

Flexible and compact: Module 18plus

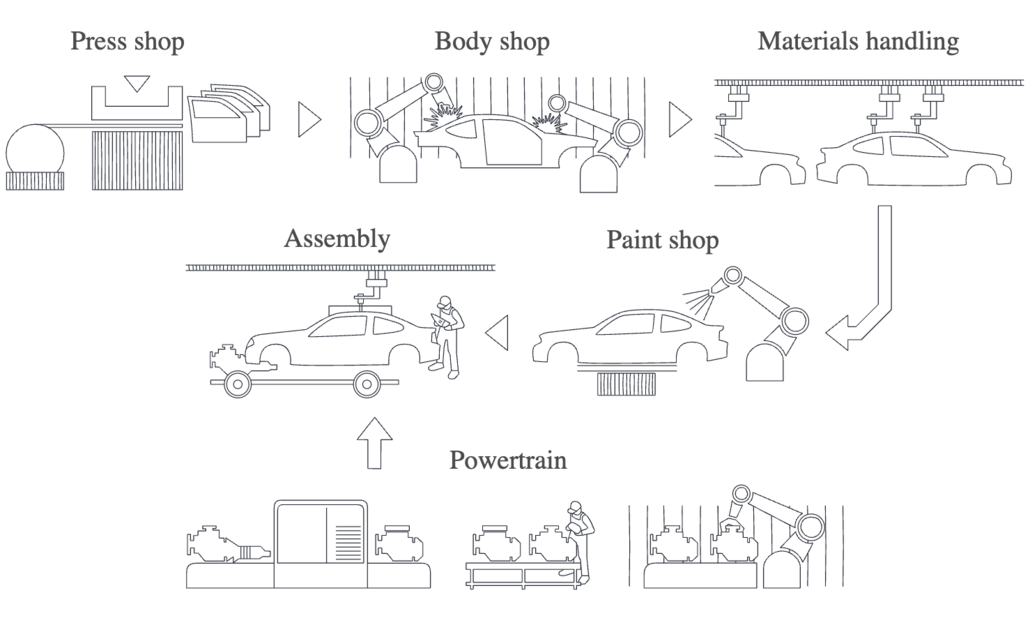

Generally, a DC 24 V control voltage is generated centrally and distributed via long cables with large cross sections. Cable attenuation can cause difficulties, e.g. voltage loss or trip failures of the MCBs. In the event of expansive applications, for instance in materials handling technology, it is much more efficient to decentralise power generation and protection which can reduce cable lengths and cross sections.

E-T-A facilitates this development with innovative and modular products which can easily be adapted to the varying requirements of the different production sectors within the automotive industry. We can also create customer-specific system solutions - we will work with you from the first idea to initial samples to the final series application.

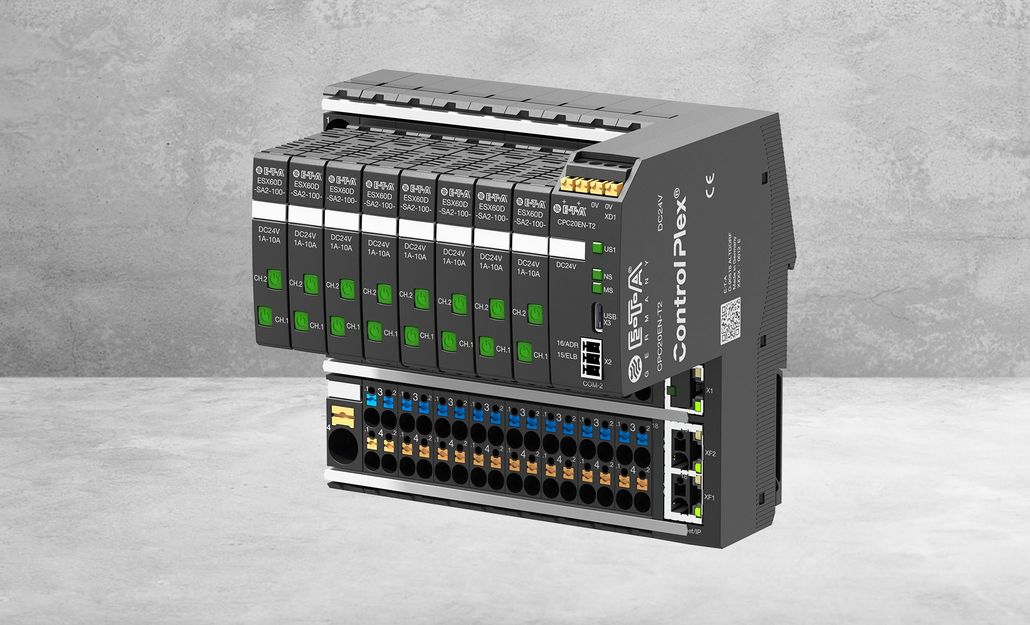

Here is a typical example of a decentralised DC24V power distribution system using the Module 18plus, which we designed in partnership with a well-known German car manufacturer. The system allows direct connection of plus, minus and functional earth to one terminal each. This supports quick wiring and system transparency.

The Module 18plus terminal block accommodates a range of plug-in type circuit breakers. The portfolio ranges from thermal-magnetic to electronic devices.

Intelligent plug-in circuit protectors, like the ESX60D-S, communicate via PROFINET with the control unit. This provides the plant operator with additional information on preventive maintenance or quick trouble-shooting. In the end, the plant is expected to run continuously.