Condition Monitoring for DC 24 V protection and power distribution

Increased machine uptime through digitisation

Collecting, saving and evaluating various machine and system data, as well as creating the digital twin, are prerequisites for a holistic predictive maintenance concept. The intelligent and communicative protection and power distribution solution of the REX system helps collect targeted data.

INTELLIGENT AND COMMUNICATIVE DIGITISATION SOLUTIONS FOR MECHANICAL ENGINEERING

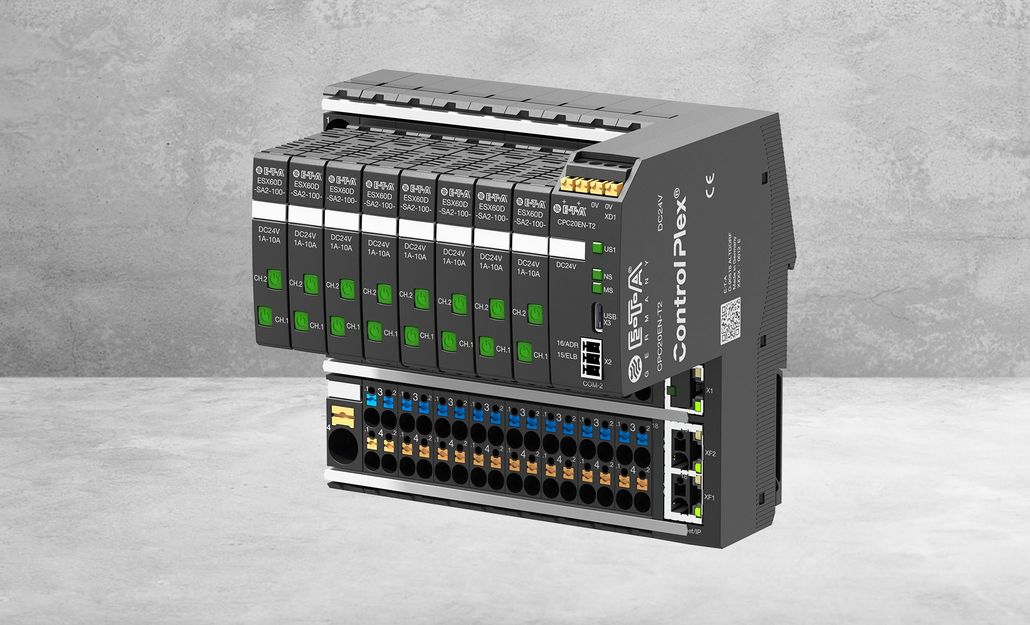

The CPC12 and EM12D ControlPlex® controllers connect the COM REX system with the superordinate communication interface. In addition to IO link and Modbus RTU, interfaces for Ethernet based fieldbus connections via PROFINET, EtherCAT, EtherNet/IP and Modbus TCP are also possible. The bus controllers record all status information and measuring values of the circuit protectors and enable their control and parametrisation.

The CPC12 ControlPlex® controllers also enable data visualisation via the web server and using it as maintenance interface. The interface enables data access also via JSON format. High transparency, clear error detection and remote access significantly increase machine uptime.

Your benefits

- Increased machine uptime through clear diagnosis and Condition Monitoring

- High flexibility through facilitated mounting/dismounting, a modular design and convenient adjustment

- Saves at least 50 % time thanks to innovative and flexible connection technology

- Saves costs as no further accessories, such as busbars or jumpers, are needed

- Saves at least 50 % space thanks to slim modules of only 12.5 mm